Charles Perdue

Well-Known Member

- Joined

- Oct 8, 2005

- Messages

- 2,177

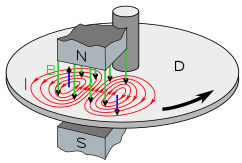

Much very good info in this article. I used it a lot when building my dyno. Mr. Lohring also helped me by emails when sizing the inertia wheel."Sounds great! I will start a dyno build in the new year using the information you have provided here and also all the information Jim Allen shared. "

Ricky, you might also be interested in my dyno article in the NAMBA Propwash. Mike Bontoft and I have mado over a thousand runs on it over the years.

Lohring Miller