You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

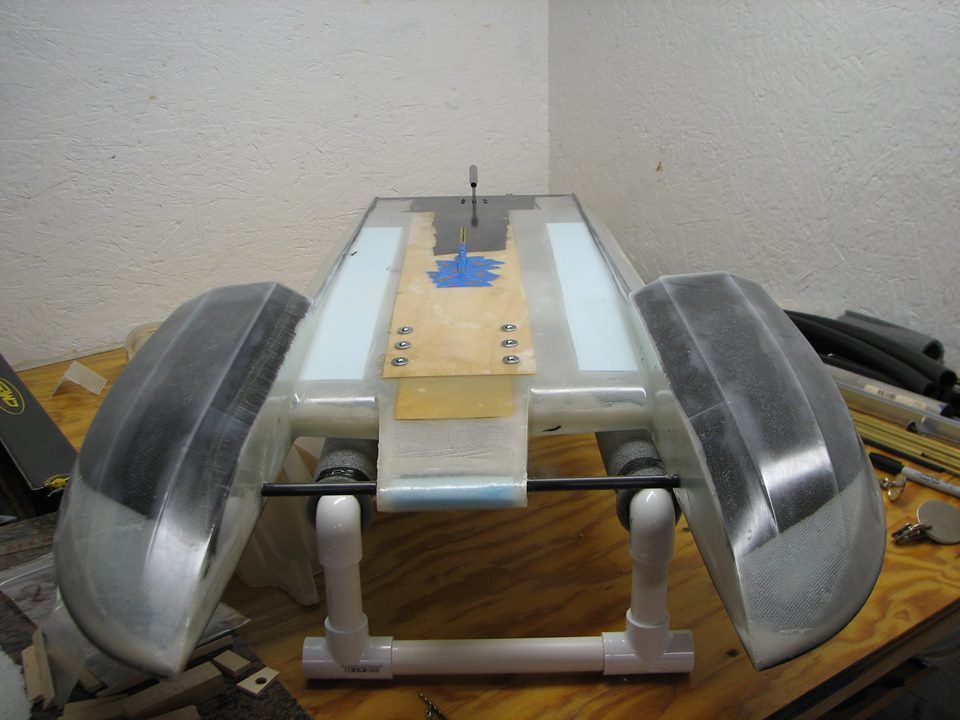

1982 Pay 'N Pak Turbine

- Thread starter Blackout

- Start date

Help Support Intlwaters:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Dasboatman

Well-Known Member

- Joined

- Jun 12, 2005

- Messages

- 1,103

Last edited by a moderator:

$133.99

$144.01

MotorGuide 8M0092071 Xi Series Pinpoint GPS Navigation Remote Replacement — For Xi3 and Xi5 Trolling Motors Includes Lanyard

Jarboys Outdoors & Marine Supplies -AUTHORIZED

$19.79

iMBAPrice 12V, 15 Amps, Heavy Duty Boat and Car Universal Remote Control Kit

AmaMax (USA) Since 1993 l iMBAPrice® Authorized Distributor

$40.08

Kit For DT9.9 DT15 9.9HP 15HP Boat Motor RC 20X35X4.5 BR Engine Replaces Motor Bering Kit 09263-20024 Replace parts

anyangliangzuoshangmaoyouxiangongsi

Dasboatman

Well-Known Member

- Joined

- Jun 12, 2005

- Messages

- 1,103

Yes it is Roy. 1987 NAMBA Nats, S.D. I believe. CHEERS!!! Bob

Blackout

Well-Known Member

- Joined

- Sep 10, 2008

- Messages

- 1,610

I will have to address that for sure. I have some ideas. One being a foam or rubber seal within the cowl to keep water from traveling up into where the carb is. Or epoxy some sort of baffle that directs water away from that area. Seen it done on gas boats all the time.hate to ask a dumb question but how do u nitro guys keep water from comeing in the nose and into the carb venture> (fe guy here ..we tape everything)

Blackout

Well-Known Member

- Joined

- Sep 10, 2008

- Messages

- 1,610

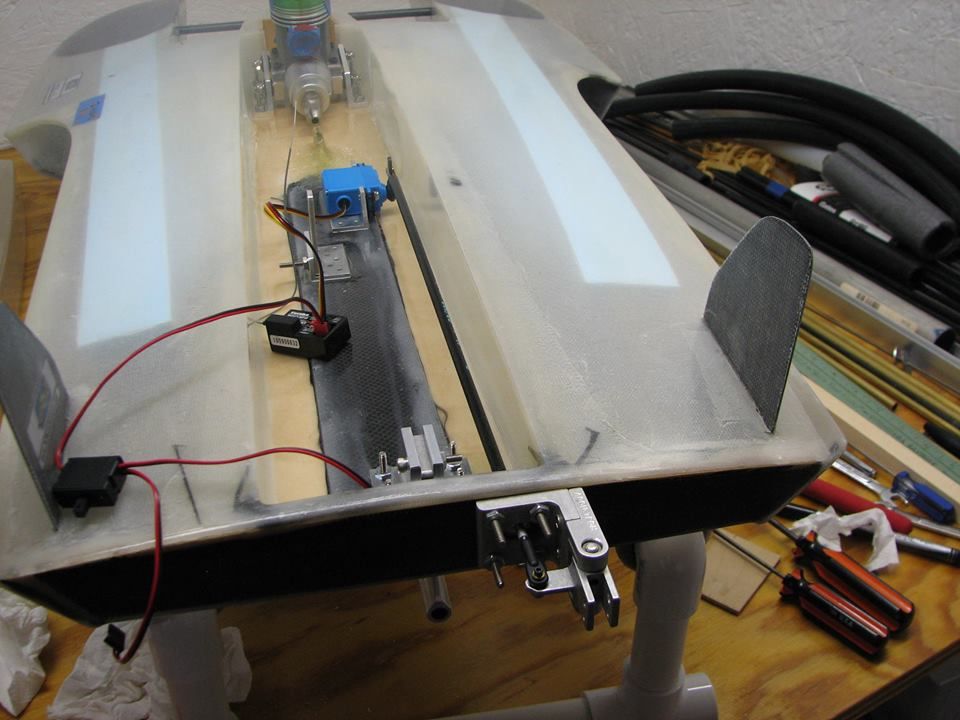

Thanks Bob!Hey Craig,

Lookin' GOOD !!!

Here's a suggestion for gaining a little room in the forward radio box. This was Jim Auguston's "Boat" in San Diego

a number of years ago. Note the raised above the deck line, sloped radio box and lid.

Where did your tuned pipe come from? CHEERS !!! Bob

The pipe is a CMB Nitro pipe with a custom 2 chamber muffler section. I build the muffler section myself and have a friend tig weld it for me. This design is similar to what I am running on my NR 46 JAE rigger. It's a straight-through design with aluminum "washers" as baffles to create the two chambers, nothing else. Kinda like a gun silencer....

BobGutsell

Well-Known Member

- Joined

- Jul 2, 2007

- Messages

- 278

Hey blackout, would you mind showing a sketch of what the inside of that muffler looks like?

Roy Munoz

Well-Known Member

- Joined

- Feb 4, 2004

- Messages

- 638

Yes it is Roy. 1987 NAMBA Nats, S.D. I believe. CHEERS!!! Bob He showed me his NOS syestem that day..Still can't believe we never met there..LOL

Blackout

Well-Known Member

- Joined

- Sep 10, 2008

- Messages

- 1,610

The inside is just two cavities for the exhaust to expand into and then have to go through the baffle holes which are the same diameter as the stinger outlet and centered with the stinger outlet.Hey blackout, would you mind showing a sketch of what the inside of that muffler looks like?

I should be very close to 80 dbA measured according to IMPBA rules.

I can show diagram later. I am on vacation for a few more days.

The muffler section is made from two lengths of 1.5" O.D., .035" wall aluminum tubing and two .035" wall aluminum washers. The washers are cut from aluminum plate using a hole saw.

Dasboatman

Well-Known Member

- Joined

- Jun 12, 2005

- Messages

- 1,103

Hey Craig,

Ah ha!! I thought the pipe looked familiar.

I few years back my buddy came up with what he thought was a MACS #1362 Muffled Marine. Tried to run it in a scale boat and engine ran VERY HOT, but quiet. Finally decider to cut the rear section off this pips and found a whole bunch of washer type baffles which increased the back pressure to the point of effectively throttling the engine down - killing performance. After some further investigation, we found that MACS Mufflers also had Super Q(uiet) Muffled marine pipe in their inventory - Stock # 1362 which we believe this pipe was.

Here is a suggestion to keep water away from the carb:

I build a ledge inside my cowls about 1/2" wide during construction. In the attached pic the area forward is filled with Styrofoam for flotation, and capped with 1/32" birch plywood. This ledge fits the top deck very closely. After painting, I cover the deck area where cowl will sit with Saran Wrap pulled tightly across the deck. Roughen the "ledge" of the now finished painting cowl with 220 wet and dry paper and clean it with rubbing alcohol. Squeeze a bead of clear silicone aquarium tank seal onto the ledge all the way back to the rear deck insert, and place the cowl in position on the hull deck - fastening whatever latch system you're using, and weight it down some. Let it set up for as long as the product used recommends, trim around inside and outside with a shape blade, and you now have a good seal between cowl and hull. The clear silicone on the ledge will also prevent the cowl from grinding through the finish on your hull deck also to keep your paint job looking better for as longer period.

CHEERS !!! Bob

Ah ha!! I thought the pipe looked familiar.

I few years back my buddy came up with what he thought was a MACS #1362 Muffled Marine. Tried to run it in a scale boat and engine ran VERY HOT, but quiet. Finally decider to cut the rear section off this pips and found a whole bunch of washer type baffles which increased the back pressure to the point of effectively throttling the engine down - killing performance. After some further investigation, we found that MACS Mufflers also had Super Q(uiet) Muffled marine pipe in their inventory - Stock # 1362 which we believe this pipe was.

Here is a suggestion to keep water away from the carb:

I build a ledge inside my cowls about 1/2" wide during construction. In the attached pic the area forward is filled with Styrofoam for flotation, and capped with 1/32" birch plywood. This ledge fits the top deck very closely. After painting, I cover the deck area where cowl will sit with Saran Wrap pulled tightly across the deck. Roughen the "ledge" of the now finished painting cowl with 220 wet and dry paper and clean it with rubbing alcohol. Squeeze a bead of clear silicone aquarium tank seal onto the ledge all the way back to the rear deck insert, and place the cowl in position on the hull deck - fastening whatever latch system you're using, and weight it down some. Let it set up for as long as the product used recommends, trim around inside and outside with a shape blade, and you now have a good seal between cowl and hull. The clear silicone on the ledge will also prevent the cowl from grinding through the finish on your hull deck also to keep your paint job looking better for as longer period.

CHEERS !!! Bob

Blackout

Well-Known Member

- Joined

- Sep 10, 2008

- Messages

- 1,610

Good suggestion for keeping water away from carb! Thanks.Hey Craig,

Ah ha!! I thought the pipe looked familiar.

I few years back my buddy came up with what he thought was a MACS #1362 Muffled Marine. Tried to run it in a scale boat and engine ran VERY HOT, but quiet. Finally decider to cut the rear section off this pips and found a whole bunch of washer type baffles which increased the back pressure to the point of effectively throttling the engine down - killing performance. After some further investigation, we found that MACS Mufflers also had Super Q(uiet) Muffled marine pipe in their inventory - Stock # 1362 which we believe this pipe was.

Here is a suggestion to keep water away from the carb:

I build a ledge inside my cowls about 1/2" wide during construction. In the attached pic the area forward is filled with Styrofoam for flotation, and capped with 1/32" birch plywood. This ledge fits the top deck very closely. After painting, I cover the deck area where cowl will sit with Saran Wrap pulled tightly across the deck. Roughen the "ledge" of the now finished painting cowl with 220 wet and dry paper and clean it with rubbing alcohol. Squeeze a bead of clear silicone aquarium tank seal onto the ledge all the way back to the rear deck insert, and place the cowl in position on the hull deck - fastening whatever latch system you're using, and weight it down some. Let it set up for as long as the product used recommends, trim around inside and outside with a shape blade, and you now have a good seal between cowl and hull. The clear silicone on the ledge will also prevent the cowl from grinding through the finish on your hull deck also to keep your paint job looking better for as longer period.

CHEERS !!! Bob

On your buddy's muffled pipe. Were the holes all centered or offset?

With my holes centered I have the option of opening the holes if the engine runs too hot. The stinger was opened up to .435", stock was .395". This pipe should run cooler than a pipe with a long internal stinger.

Does anyone run a cooling clamp on their CMB headers? If so, where can you get one from. I have a nice aluminum one for a 7/8" header, but not for the CMB .67 header. I have used soft copper tubing, but prefer a purpose machined cooling clamp. Thanks.

Dasboatman

Well-Known Member

- Joined

- Jun 12, 2005

- Messages

- 1,103

The ones in the MACS pipe were staggered as I recall. You could not see through the pipe like the MACS muffled Marine I use on occasion.

The pipe on my boat that I showed earlier (post 44) came from Alan Hobbs. It's a Russian made pipe I believe, very similar in operation to the AB or CMB Muffled pipes. I prefer it because it is made of thicker material than the very thin CMB pipes.

I have not seen any coolers on CMB headers. The coupler is far enough back where they seem to hold up well. No real need to cool that

I have seen to rationalize the additional weight. CHEERS !!! Bob

The pipe on my boat that I showed earlier (post 44) came from Alan Hobbs. It's a Russian made pipe I believe, very similar in operation to the AB or CMB Muffled pipes. I prefer it because it is made of thicker material than the very thin CMB pipes.

I have not seen any coolers on CMB headers. The coupler is far enough back where they seem to hold up well. No real need to cool that

I have seen to rationalize the additional weight. CHEERS !!! Bob

Last edited by a moderator:

Blackout

Well-Known Member

- Joined

- Sep 10, 2008

- Messages

- 1,610

Will 20 ounces be enough fuel for heat racing? I run 50% nitro, 67 CMB engine. I have two 10 ounce tanks under each side of the deck. Wondering if I should add a 3rd 4 ounce tank? There should be room. Will I be running into any issues with siphoning fuel between three tanks?

Thanks!

Thanks!

Hydro Junkie

Well-Known Member

- Joined

- Oct 2, 2006

- Messages

- 5,821

My boat runs twin 10's and has more than enough to finish a mill and 5 laps so you should be good to go

Blackout

Well-Known Member

- Joined

- Sep 10, 2008

- Messages

- 1,610

HJ, 5 laps? I'll be running 6 laps on a 1/6 mile oval. How many seconds do you go in before the start? Thanks.

Also, I will be tapping the rear sponson for the turn fin soon. Any suggestions on placement? It's an Accu-Tech 1/8 scale fin. Thanks.

Also, I will be tapping the rear sponson for the turn fin soon. Any suggestions on placement? It's an Accu-Tech 1/8 scale fin. Thanks.

Similar threads

- Replies

- 38

- Views

- 8K

- Replies

- 4

- Views

- 2K