MikeConyers

Member

- Joined

- Feb 23, 2017

- Messages

- 19

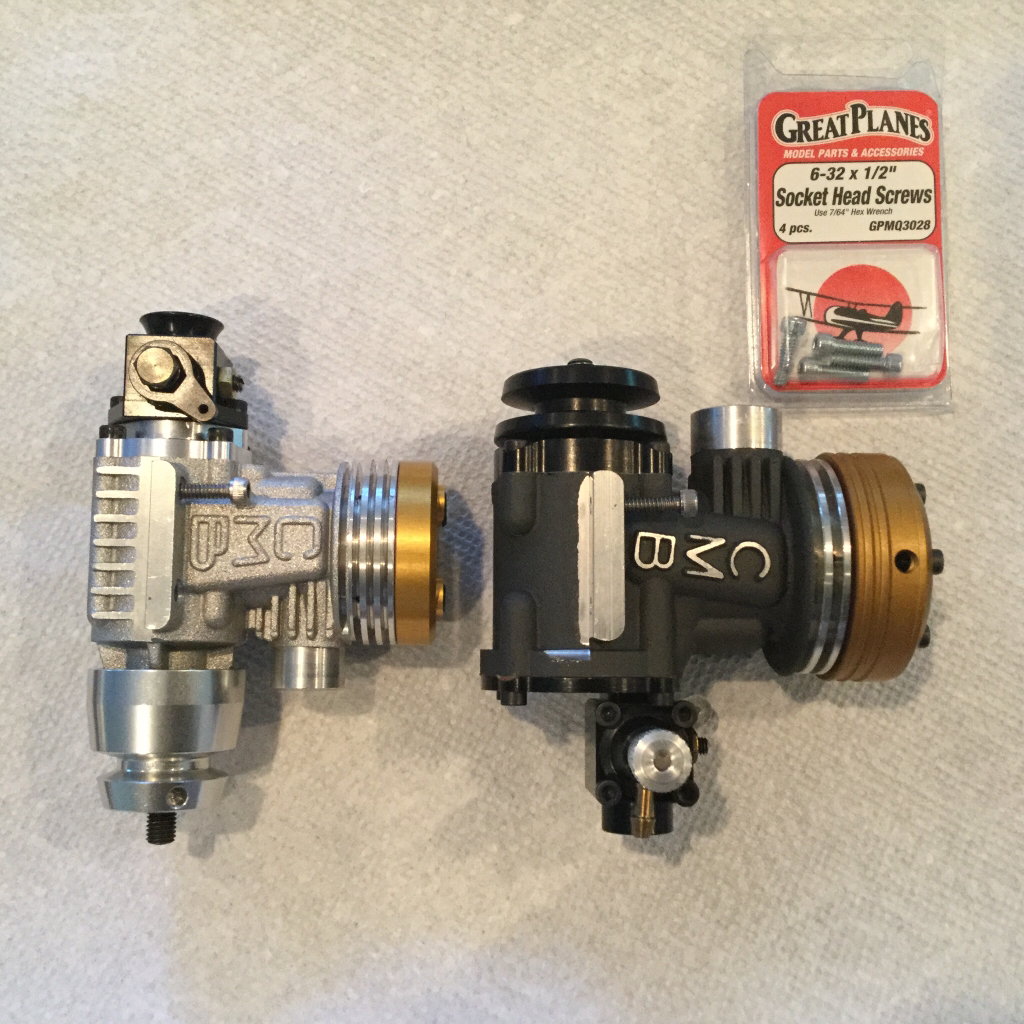

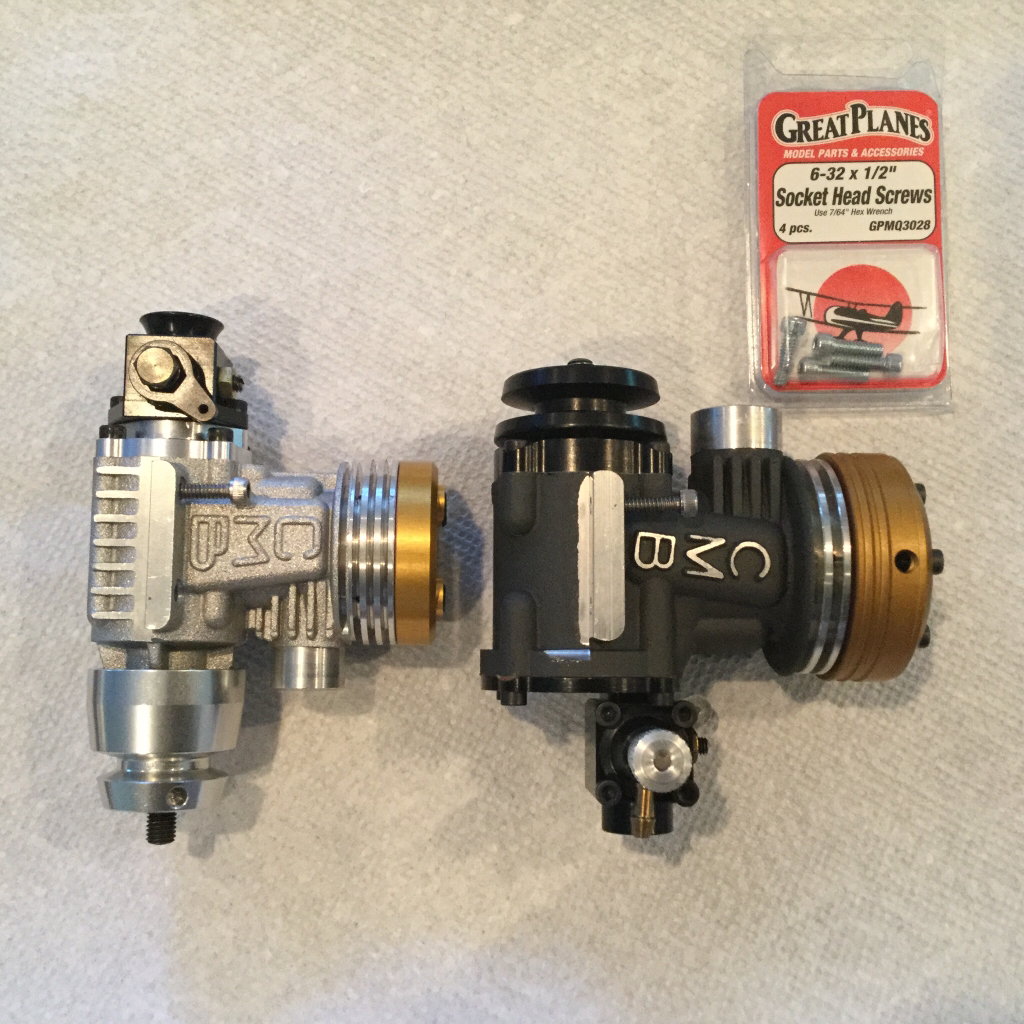

Just getting back into RC boats after 15+ hiatus. So pretty much learning all over again. I have two brand new motors but I'm having trouble mounting them. Using 6/32 screws which fit perfectly into my motor mounts but won't budge in the non tapped holes of the motors.

Also, 4/40 screws are too small.

Should I use 6/32 tap on the holes?

Thought about using a 1/8 drill bit to open the hole, but didn't know if that would make it too large.

I understand that I could turn down the OD on the screws but not exactly familiar with how to do that w/o a lathe.

Just looking for some advice! Thx!

Sent from my iPad using Tapatalk

Also, 4/40 screws are too small.

Should I use 6/32 tap on the holes?

Thought about using a 1/8 drill bit to open the hole, but didn't know if that would make it too large.

I understand that I could turn down the OD on the screws but not exactly familiar with how to do that w/o a lathe.

Just looking for some advice! Thx!

Sent from my iPad using Tapatalk