Hydro Junkie

Well-Known Member

- Joined

- Oct 2, 2006

- Messages

- 5,800

Ray, please tell me you used Loc-Tite(or an equivalent) on those screws you installed in the collars

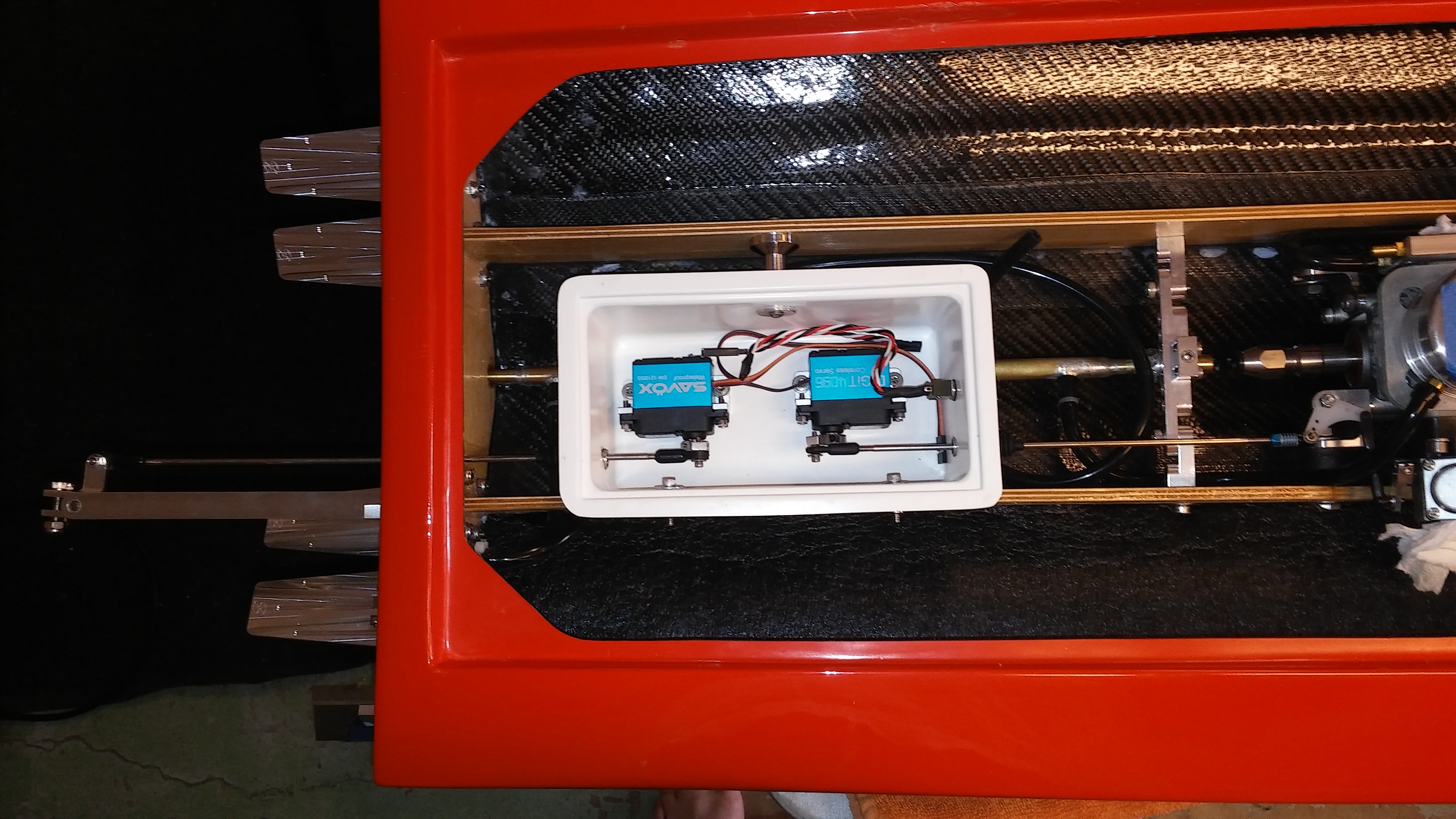

I made this as a solution.. most every servo is water proof! And this is my setup for a tight tub rigger fits the bill nicely for a rh push short 4-40 setup... why doesn’t a big name make these lol gold mine !Something you probably don't want to hear, but for your next build, address the disease instead of the symptoms ( flex ). Mount your rudder servo as close to the transom as you can. There are many excellent waterproof servos on the market and engine rail mounting is a good option. Use a rudder horn ( ie; Speedmaster ) that has the rod link on the starboard side to "pull" the rudder through a right turn. A short/stiff pull rod is not going to have to be over-engineered to stop anything.

When you rig a boat, ask yourself WHY you are doing things as you are, before-hand. Be your own builder.

Send me the details and this "big name" will gladly make them. Lawless DrivesI made this as a solution.. most every servo is water proof! And this is my setup for a tight tub rigger fits the bill nicely for a rh push short 4-40 setup... why doesn’t a big name make these lol gold mine !

That is pretty much what my steering rod set looks like, except I use raw aluminum rod and industrial molded plastic rod ends at the servo end. Straight or right angle rod ends at the drive end. With two pairss of rods joined with a clamp in the middle, the length is easily adjustable.here are what I'm using for heavy duty steering pushrods- machined aluminum alloy suspension arms with heavy duty threaded steel ball-link rod ends (3mm ID). No flex. They comne in various sizes, and sets. Beautifully anodized:

https://www.ebay.com/itm/8pcs-Alumi...rand=Unbranded&_trksid=p2047675.c100005.m1851(this is just one example, there are quite a few similiar products out there)

Enter your email address to join: