- Joined

- Jul 14, 2008

- Messages

- 433

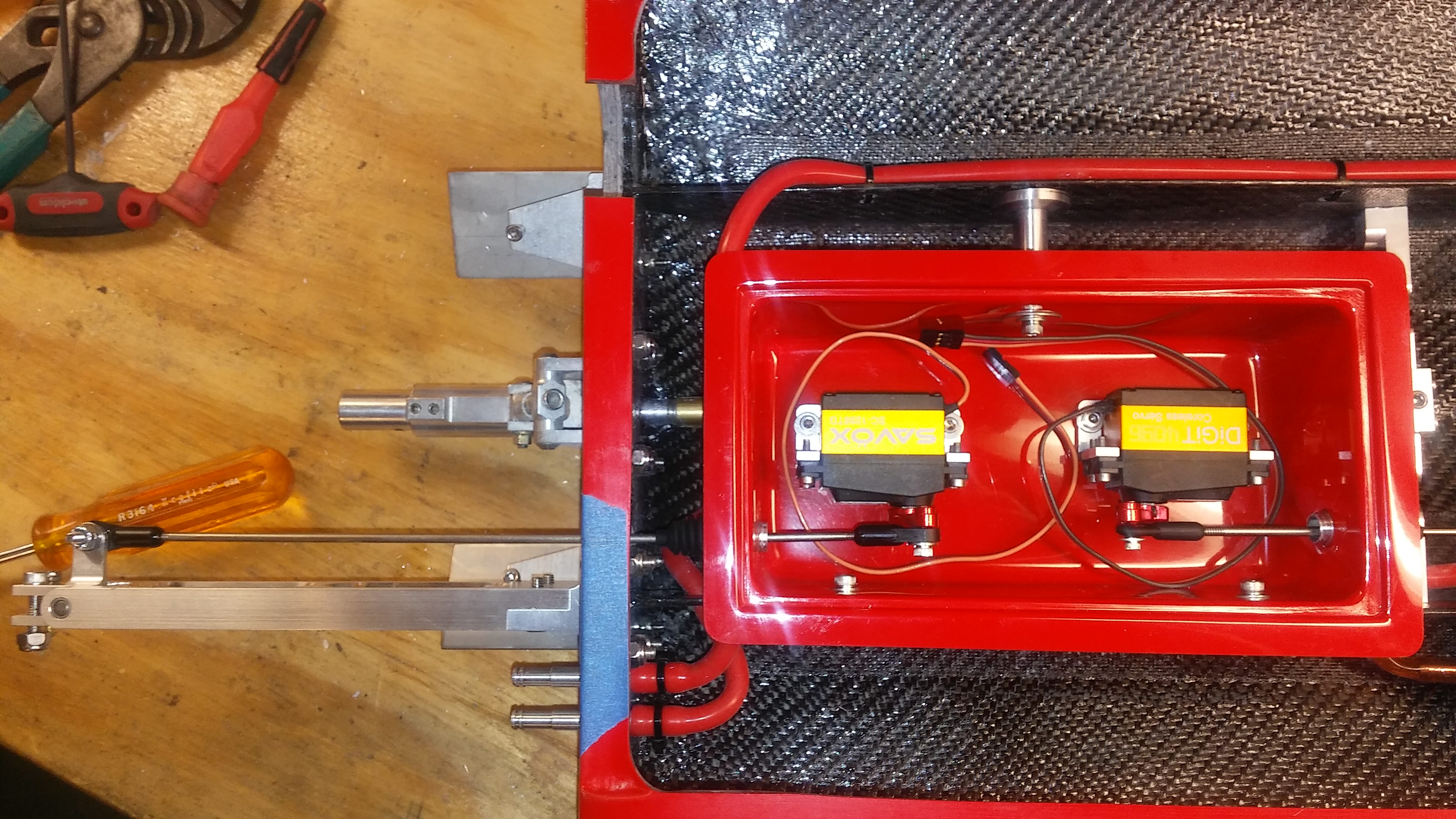

Hey all, I’m putting together a 7.5 Lee Craft for the NAMBA Nats this year and I’ve been looking for those tapered inserts you put into the carbon fiber stealing rods. Does anyone have a great source for those or an alternate for building out the steering pushrods on a 7.5 outboard?