XtremeRcBoats

Well-Known Member

- Joined

- Jan 31, 2002

- Messages

- 1,242

What a nice pipe bracket, thanks for the link. I'm going to try one myself

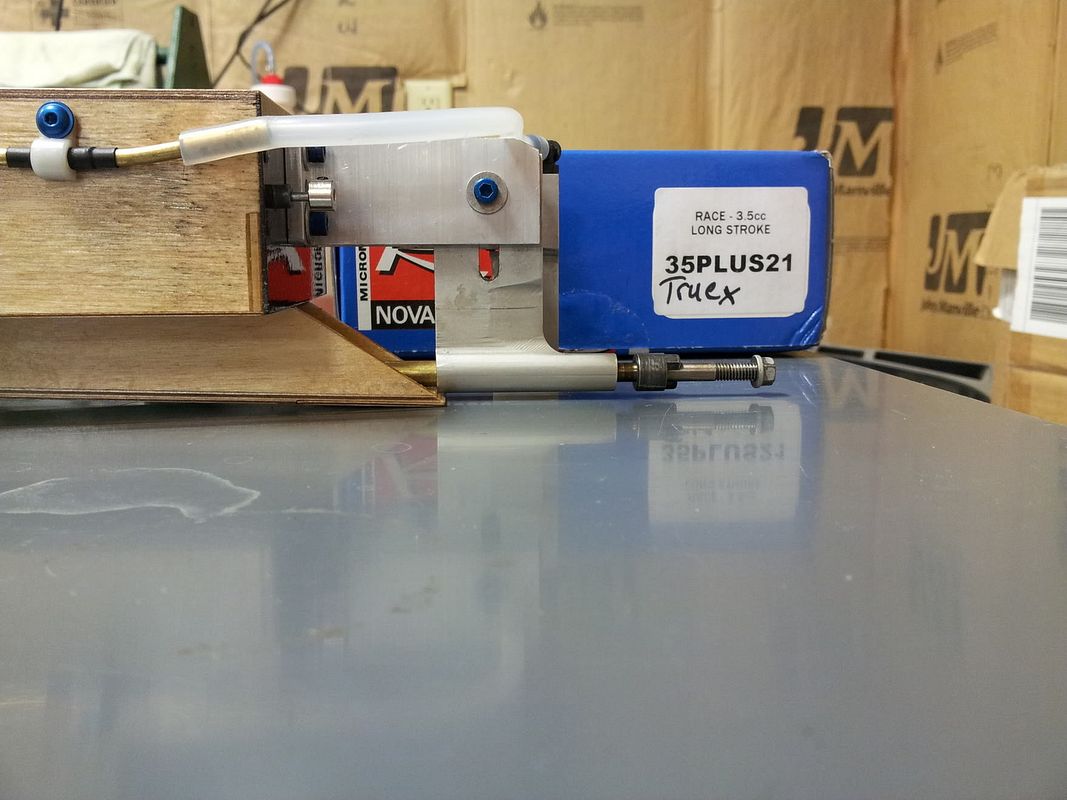

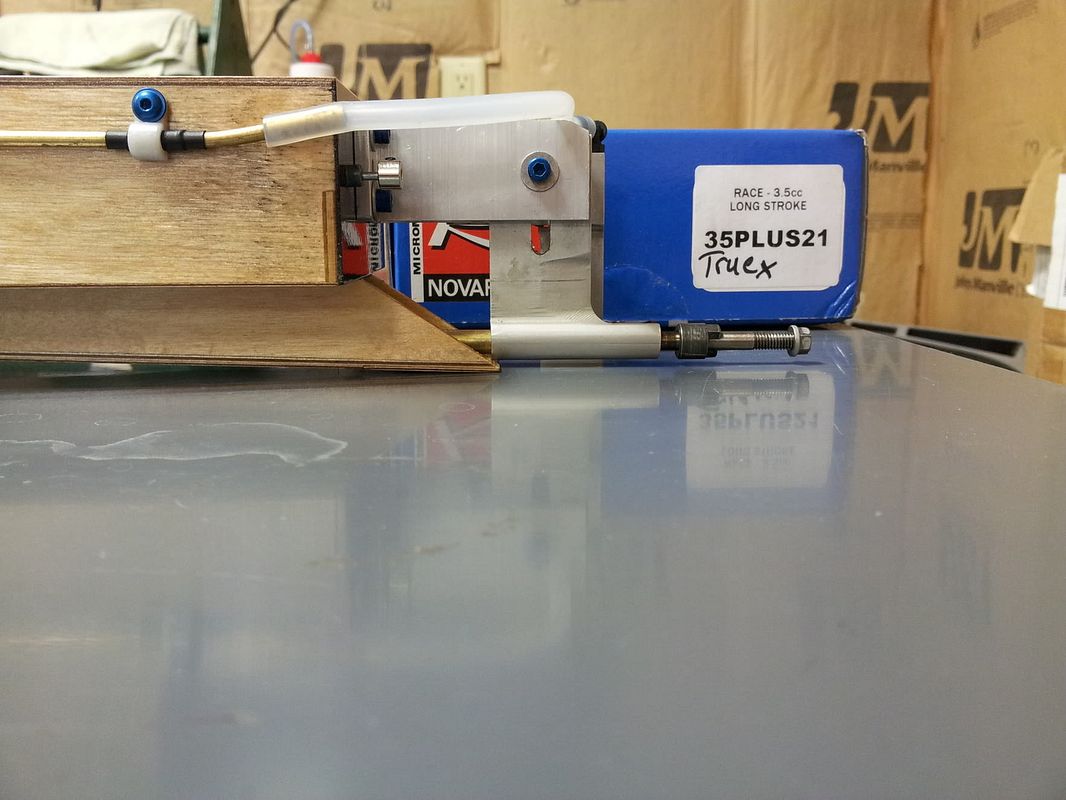

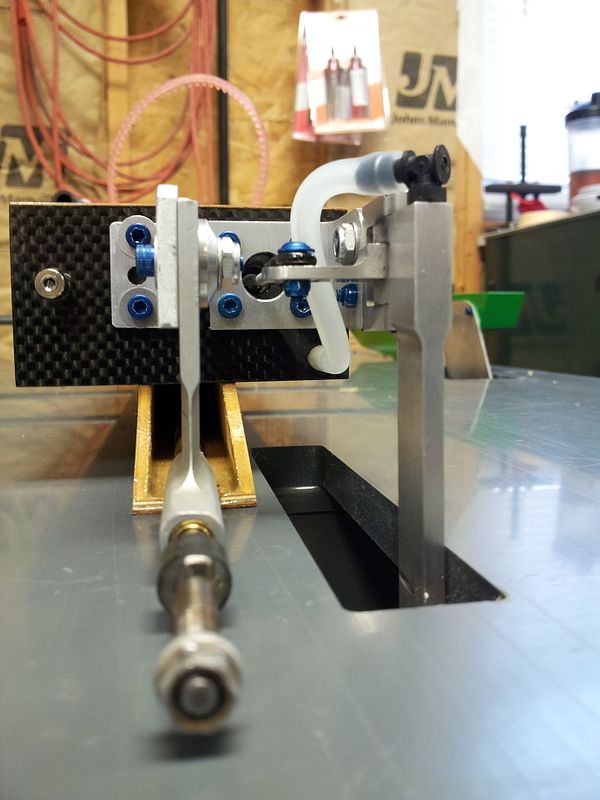

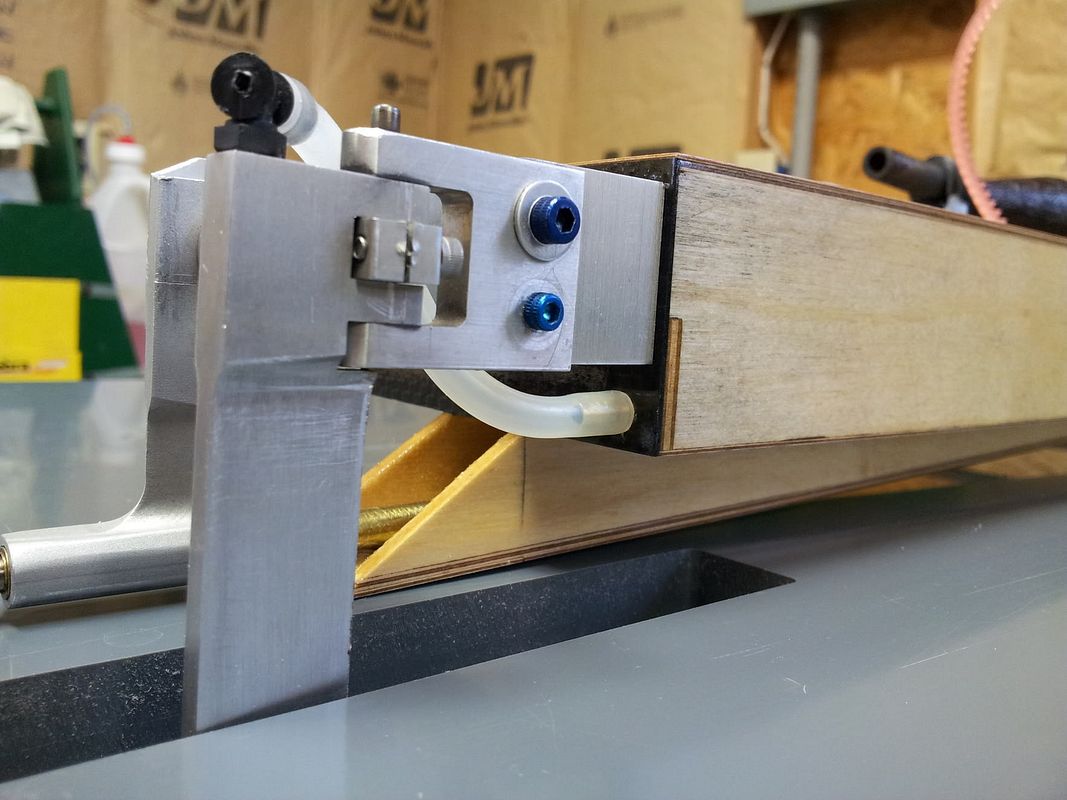

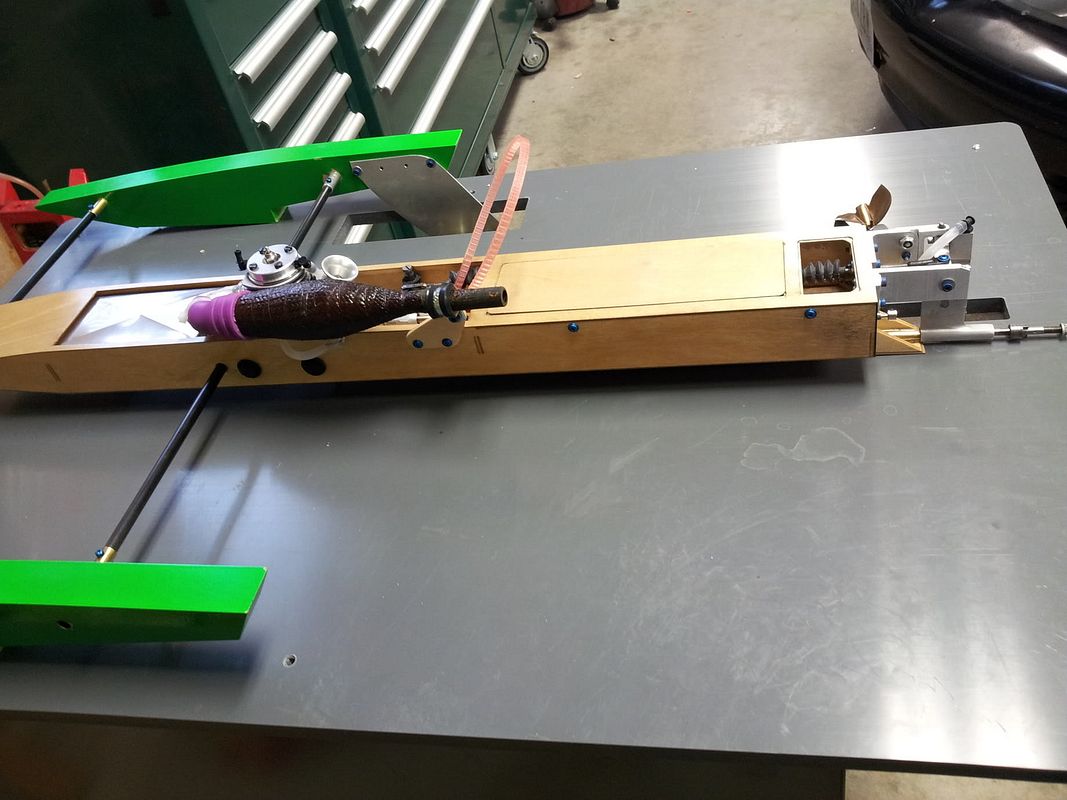

I agree with this. Here is a couple pictures of mine:This a must. Getting your strut as low as possible I beveled out the inside of the ski ,were the brass stuffing tube lies .you don't need much.Your strut lays even with the bottom ski Notice were the ski stops

Nice looking boat Rod! (Except that external water line plumbing!got mine cleared and put back together to take a final weight. Not bad! The weight is RTR minus fuel (cowl, lid, battery, prop, flex shaft, etc etc etc all included in that weight) The sponson fell off the hook when I was clearing it, and chipped it all to heck. But oh well, it wont win any awards for a nice paint job, but should move along pretty well

Lol! Your the second person to say that. But it works! I might have to see what I can do about that here if I get some timeNice looking boat Rod! (Except that external water line plumbing!got mine cleared and put back together to take a final weight. Not bad! The weight is RTR minus fuel (cowl, lid, battery, prop, flex shaft, etc etc etc all included in that weight) The sponson fell off the hook when I was clearing it, and chipped it all to heck. But oh well, it wont win any awards for a nice paint job, but should move along pretty well

)

Here you go brother, this betterNice looking boat Rod! (Except that external water line plumbing!)

Enter your email address to join: