- Joined

- Dec 11, 2003

- Messages

- 1,312

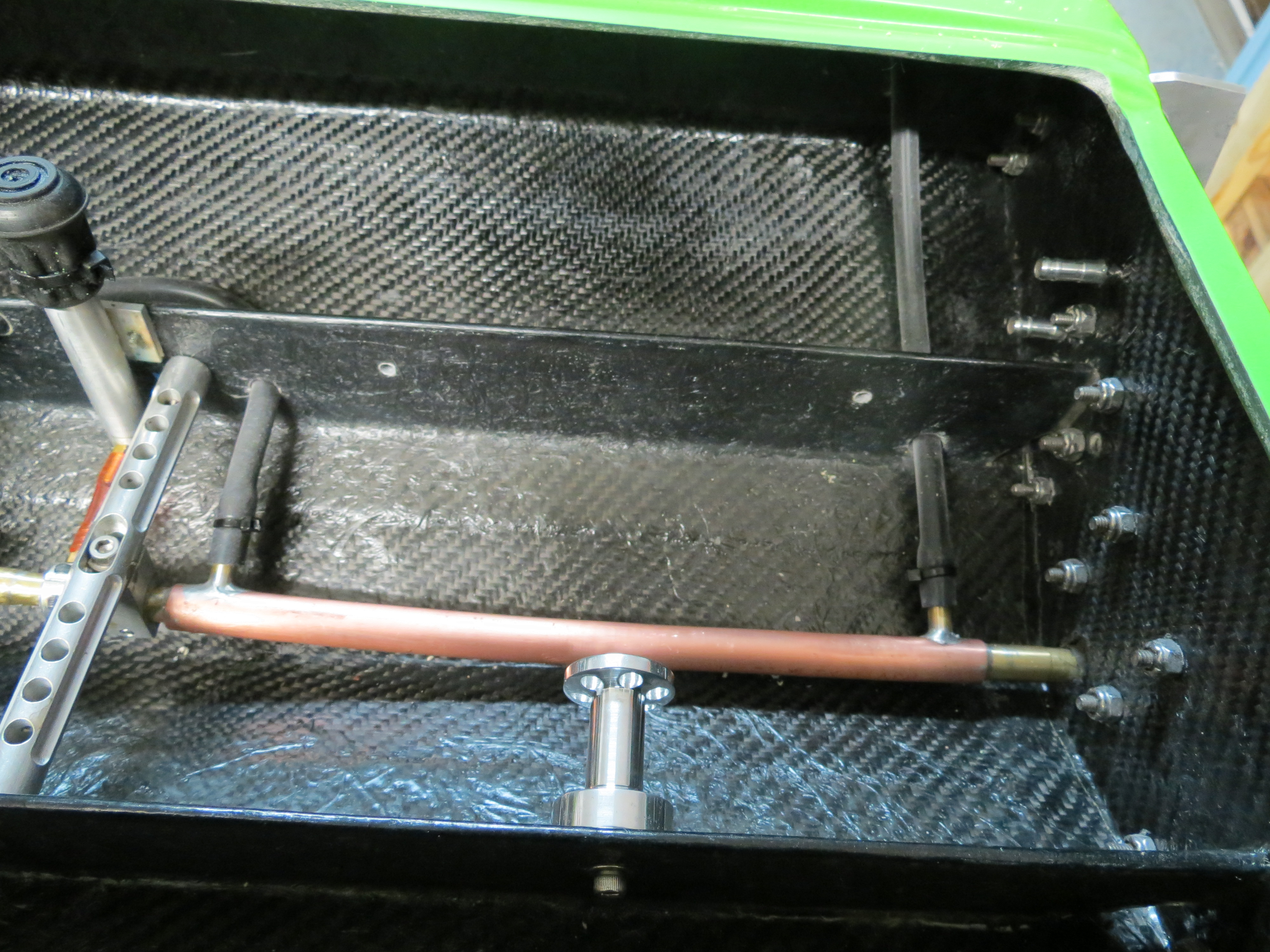

2yrs ago I suffered a catastrophic drive failure while chasing the season championship. In the last heat of the last race my mono drive wrapped up on itself. It was due to the fact it didn't have enough lube...I probably didn't grease the shaft before that heat and I paid for it. Fast forward this season...my new mono I think I have that problem solved. this drive has three ports for oil...one closest to the motor was thanks to Wally...I saw it in his mono and chased down the pill bottles from win dixie while I was in Florida christmas..I probably cleared out all they had on the shelf that day. What you guys think...did I miss anything?