Blackout

Well-Known Member

- Joined

- Sep 10, 2008

- Messages

- 1,610

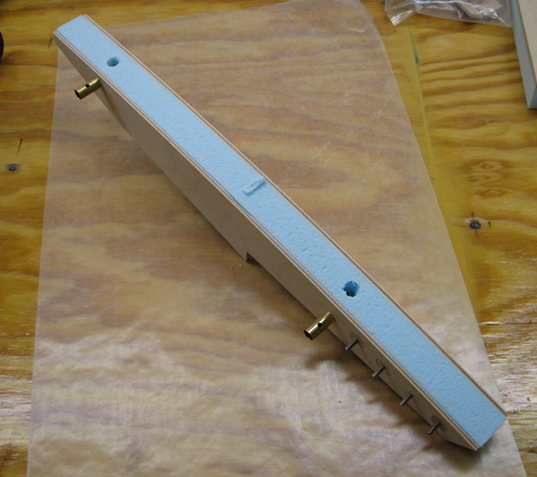

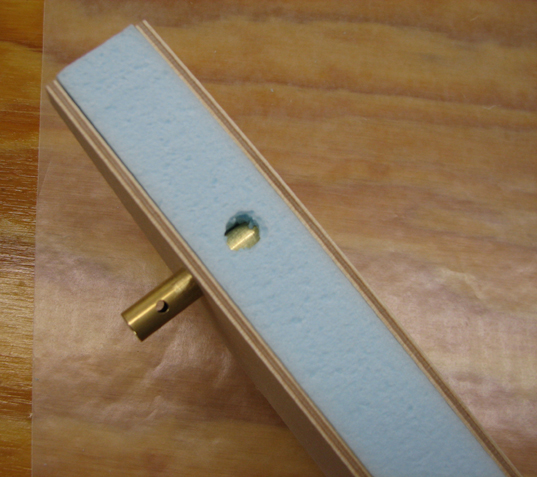

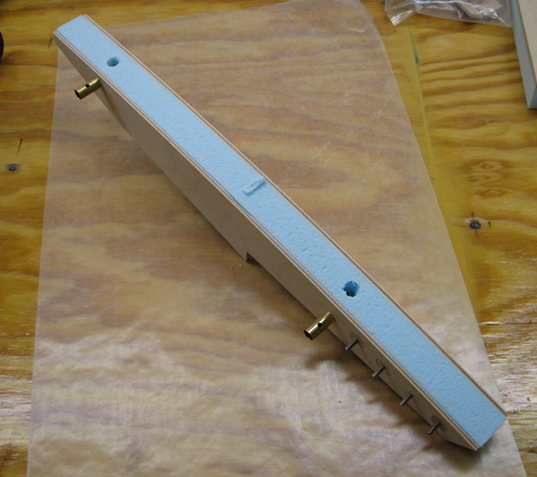

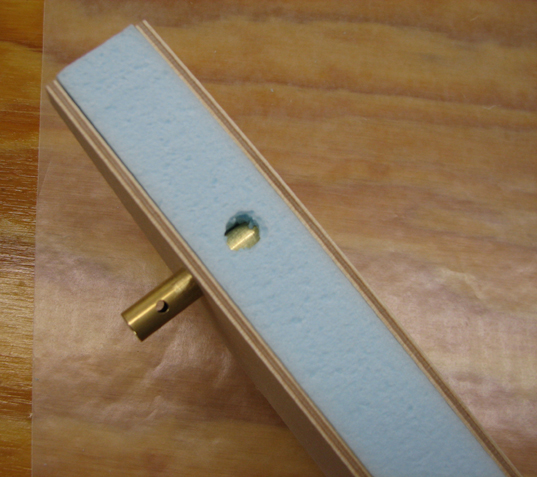

I think I figured out a good way to make sure the sponson tubes don't pull out from lack of epoxy. As mentioned in the instructions, you have to make sure there is enough epoxy on the tubes, but at the same time keep the epoxy out of the inside of the tube. This can be tricky because some of the epoxy is cleaned off when you slide the tube in. I decided to drill holes in the top of the sponson foam and fill the holes with 30 min. epoxy. Let gravity bring the epoxy down and around the tube a bit. Use a toothpick to get any air bubbles out. Add enough epoxy so that the hole is filled atleast 1/4" above the tubing or fill it all the way if you are not concerned about weight. Below are pictures. Any thoughts are welcome.