Dirk Jan Cozy

Well-Known Member

- Joined

- Feb 3, 2022

- Messages

- 189

Hello fellow rc boaters, I started building a 32" Wild Thing designed by John Finch.

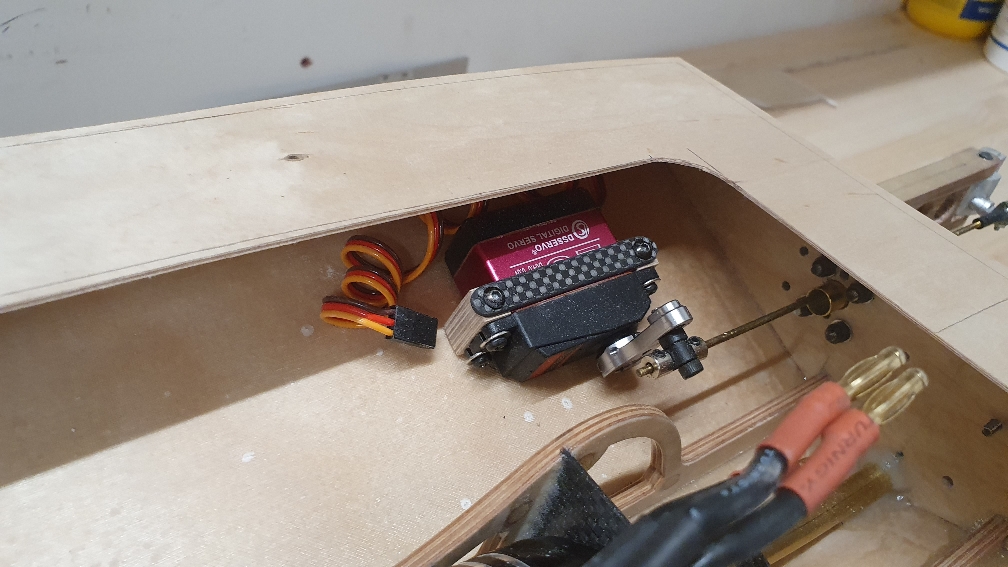

I plan to run it on 6S, with a 3674 or 4082 motor around 1650kV. Esc will.be a 150A Flycolor.

I changed the design slightly; different ribs and 10mm higher hull at the transom.

Why I did that: because I thought it would be convenient to accomodate the FE setup. Only I found out later, that John Finch successfully transferred his Wild Thing to an FE setup, without any issues!

So to be clear: my design changes are actually not necessary and by these changes I certainly don't want to pretend to 'know things better'. John Finch designed a great looking hull which performs well too!

Allright, let's start the build. I printed the ribs and plating / sheeting.

Cutting the ribs:

Setup on a flat build board

Gluing the bottom sheeting with thickened epoxy. The aluminum profiles keep the running surface nice and straight.

First glue the straight part. The next day, glue the bended section. Got that from Mr. Finch his build

The sides have been glassed on the inside, before gluing them to the hull.

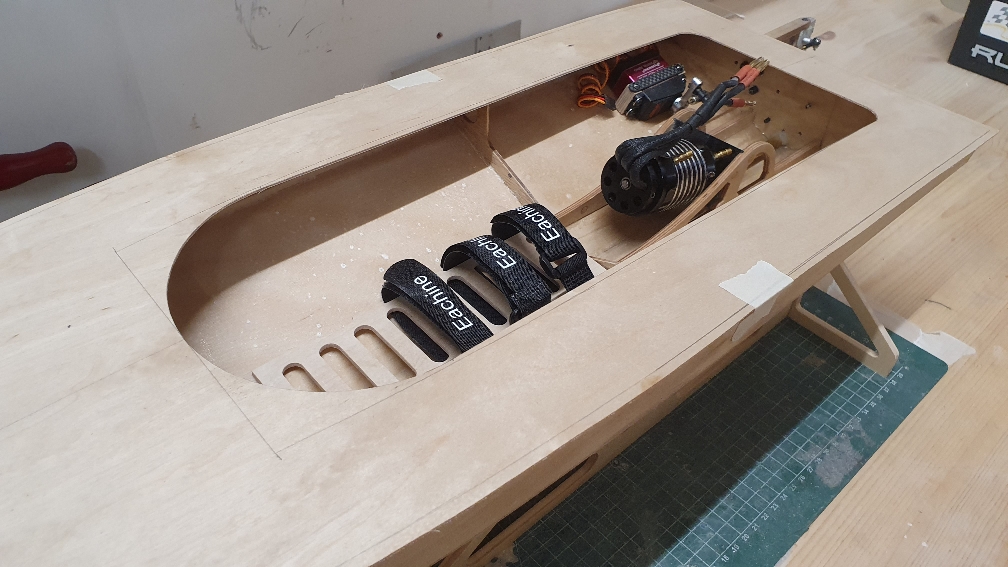

This is the hull so far:

Next up, some more glassing. Then I can release the hull from the board!

I plan to run it on 6S, with a 3674 or 4082 motor around 1650kV. Esc will.be a 150A Flycolor.

I changed the design slightly; different ribs and 10mm higher hull at the transom.

Why I did that: because I thought it would be convenient to accomodate the FE setup. Only I found out later, that John Finch successfully transferred his Wild Thing to an FE setup, without any issues!

So to be clear: my design changes are actually not necessary and by these changes I certainly don't want to pretend to 'know things better'. John Finch designed a great looking hull which performs well too!

Allright, let's start the build. I printed the ribs and plating / sheeting.

Cutting the ribs:

Setup on a flat build board

Gluing the bottom sheeting with thickened epoxy. The aluminum profiles keep the running surface nice and straight.

First glue the straight part. The next day, glue the bended section. Got that from Mr. Finch his build

The sides have been glassed on the inside, before gluing them to the hull.

This is the hull so far:

Next up, some more glassing. Then I can release the hull from the board!